Roland Jupiter 4 NEW PSU

About Roland Jupiter 4 PSU (power supply) replacement

This modern and state of art PSU is suitable to replace an old PSU in Roland Jupiter 4 synthesizer. It is an universal input (85 to 265V AC) switch mode power supply (SMPS).

In comparison to original PSU it has several advantages

- NO OVERHEAT! This PSU runs lukewarm inside the synth

- Efficiency around 78{eb681a58ecc476759952a50a8a7c167279151df38e58f2598760f2d2e5f4f286} (incl. linear regulators) (efficiency of original PSU is 55{eb681a58ecc476759952a50a8a7c167279151df38e58f2598760f2d2e5f4f286})

- No audible NOISE

- Precise Over Current Module that monitors possible fault conditions

- Less weight (320g incl. metal cover and insulator board)

- New and quality electronic parts

- Performance and quality optimized

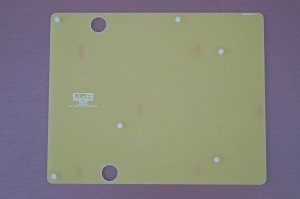

- Top metal protection cover and bottom insulator plate that covers all components under high voltage

- Compact construction

- Easy to install

- For sale complete PSU module incl. insulator board and protection metal cover + all necessary parts to install the PSU

- Price: 250€ net

Technical information

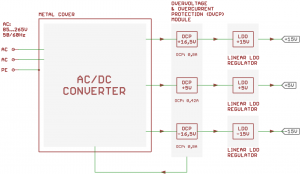

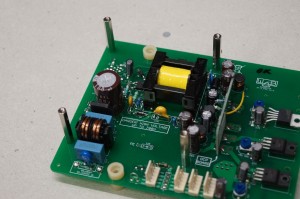

Below block diagram of PSU is depicted. It consists of AC/DC converter, Overcurrent Protection (OCP) Module and LDO regulators

AC/DC converter

The converter has an universal 85…265VAC 50/60Hz input. It has internal over-load/temperature protection. If over-load/temperature event occurs, the AC/DC converter latches off (to be precise, it stops to switch and produce output voltages; the converter primary high voltage stage is still powered with a line voltage). Disconnecting of the PSU from the line voltage will reset the converter and if no fault condition is present it will start to work normally.

AC/DC converter uses multiple output flyback topology. The feedback senses +16,5 and -16,5 rails. Output voltages are approx. +16.5V, +7V, -7V, -16.5V that are further regulated by LDO regulators.

Overcurrent Protection (OCP) Module

Overcurrent Protection Module has precise current sensors for every rail. OCP module output is connected to the AC/DC converter controller IC. If any of following events occurs, the AC/DC converter will latch off (as described above in the „AC/DC converter“ part):

- Current on +15V rail raises to 0,80A (normal Jupiter 4 +15V rail consumption is 0,5A)

- Current on +5V rail raises to 0,42A (normal Jupiter 4 +5V rail consumption is 0,2A)

- Current on -15V rail raises to 0,80A (normal Jupiter 4 -15V rail consumption is 0,4A)

Current sensors have tolerances +-2{eb681a58ecc476759952a50a8a7c167279151df38e58f2598760f2d2e5f4f286}

Linear LDO regulators

LDO regulators in every rail regulate the AC/DC output voltages to precise +15, +5, -15V. Every regulator has its own trimpot for precise voltage adjustment.

As conclusion, this PSU has superior protection against fault conditions:

Dual OVP protection:

- LDOs in series

- controller IC OVP circuit

Double overcurrent protection:

- coarse over-current and short circuit protection as a part of controller IC circuit

- precise current sensors as a part of OCP module

Installation instructions

PLEASE NOTE! We sell a fully working and tested PSU with few additional parts to mount the PSU into the Polysix. Following installation is an example. We are not responsible for health injuries and material damages that can cause bad installation of this PSU. Only a qualified tech should make this PSU swap. You are doing the PSU swap on your own risk

DISCONNECT POWER CORD FROM THE MAINS PLUG

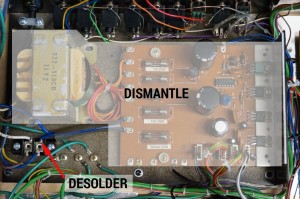

Remove old transformer and linear regulator PCB

Cut white and brown wires coming out from the primary of transformer approx 3 cm from it

Cut blue wire coming from mains switch

Unscrew these 3 screws to dismantle the heatsink

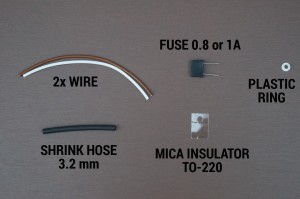

Solder new 0,8/1A fuse. The solder joint must be strong and clean!!

Use heat-shrink tubing for insulation

Now, back to the original PCB. Dismantle the aluminium plate because it will be used again

Unscrew 4x screws on the top and 2x on the bottom

Now, install the plate as depicted. Use original screws

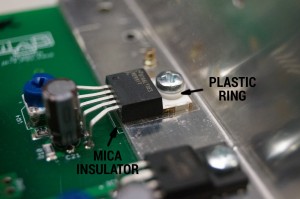

Now installing of the mica TO-220 insulator

Unpack it carefully from the paper cover

Put there the mica insulator so that both holes are CENTERED! This is very important to avoid a damaging of the insulator when installing the LDO

Use original screw and put the TO-220 insulator ring on it. Then put it into the regulator’s hole and screw carefully to the heatsink. Again, be very soft and pay attention that the mica insulator doesn’t move to the side. Otherwise it will be damaged and the metal tab of LDO will be electrically connected to the heatsink what is forbidden.

Using of heatsink paste is not necessary due to very low dissipation on LDO regulators

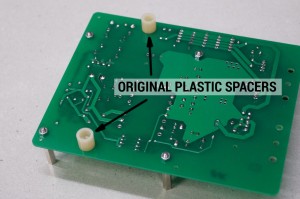

Re-use original plastic spacers

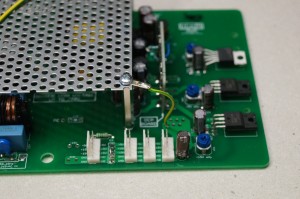

Put new PSU on the place of the old PSU PCB

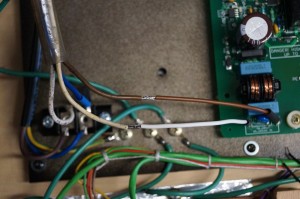

Remove insulation from white and brown wires and prolong them with supplied wires and insulate the solder joint with heat shrink tubing

Solder all the wires as depicted

Two auxiliary black wires (GND) and two blue wires (-15V) are soldered as depicted

Part of manufactured JP-4’s are originally connected on the upper side of PCB (when looking on the pic). In this case connect these to the new PSU also in the same way as depicted

Check solder joints again!

Install insulator plate

Use original screws to mount the heatsink again

Connect earth cable between main carrier aluminium plate and the PSU’s metal cover

Also connect another wire from the PSU’s GND to metal plate

Mark universal input with a label on the rear of the synth. Cover original voltage rating to avoid confusion

CHECK EVERYTHING AGAIN: all solder joints are good? no short circuit present (caused by solder)?

Before connecting of +5, +15, -15 connectors to synth boards, check the PSU voltages with scope or DVM. If everything is OK plug the connectors

READY!

Some safety recommendations when working with the PSU

- Be careful, the big bulk electrolytic cap is still charged with high voltage (for 115VAC it is 165V and for 230VAC it is 330V) after the PSU was turned or latched off

- When de-installing the PSU, short + and – terminals of the bulk cap (bottom side of the PCB) with a 470 ohm / 5W resistor for 1 second. At this time, PSU should be disconnected from the line voltage

- Line voltages in the JP-4 are still present, even if switch is turned off! Be careful with line wires!